Integrated with cutting-edge TDI detectors

Various TDI detectors are for your choice, which match your requirements.

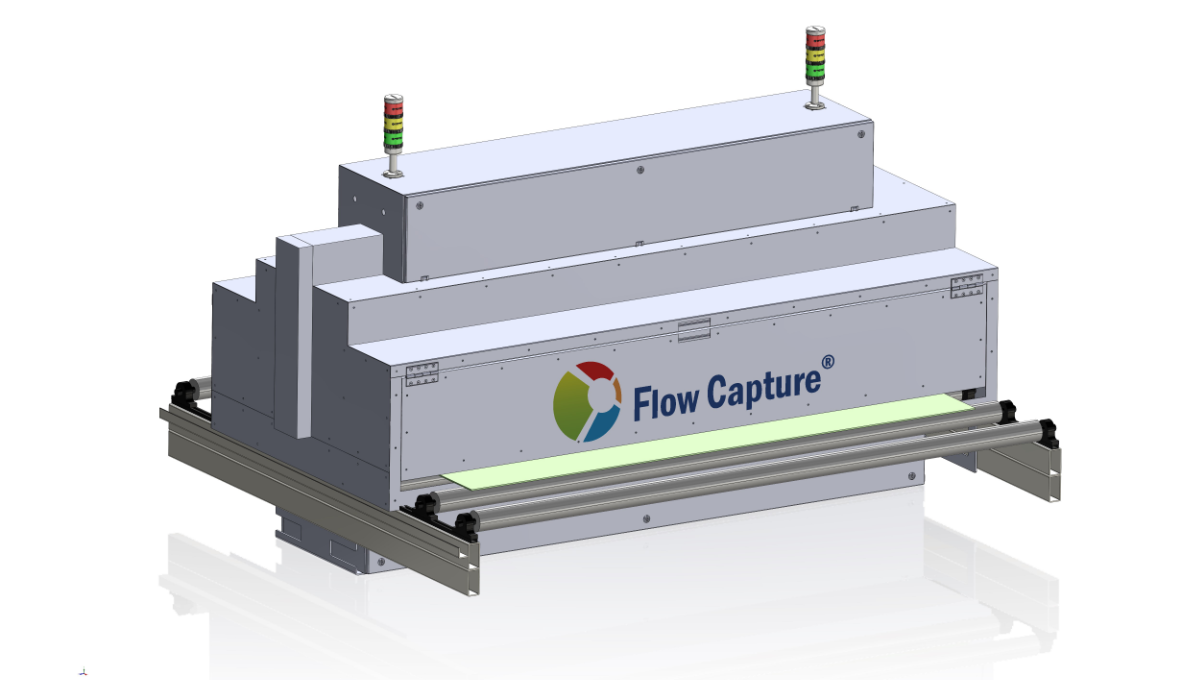

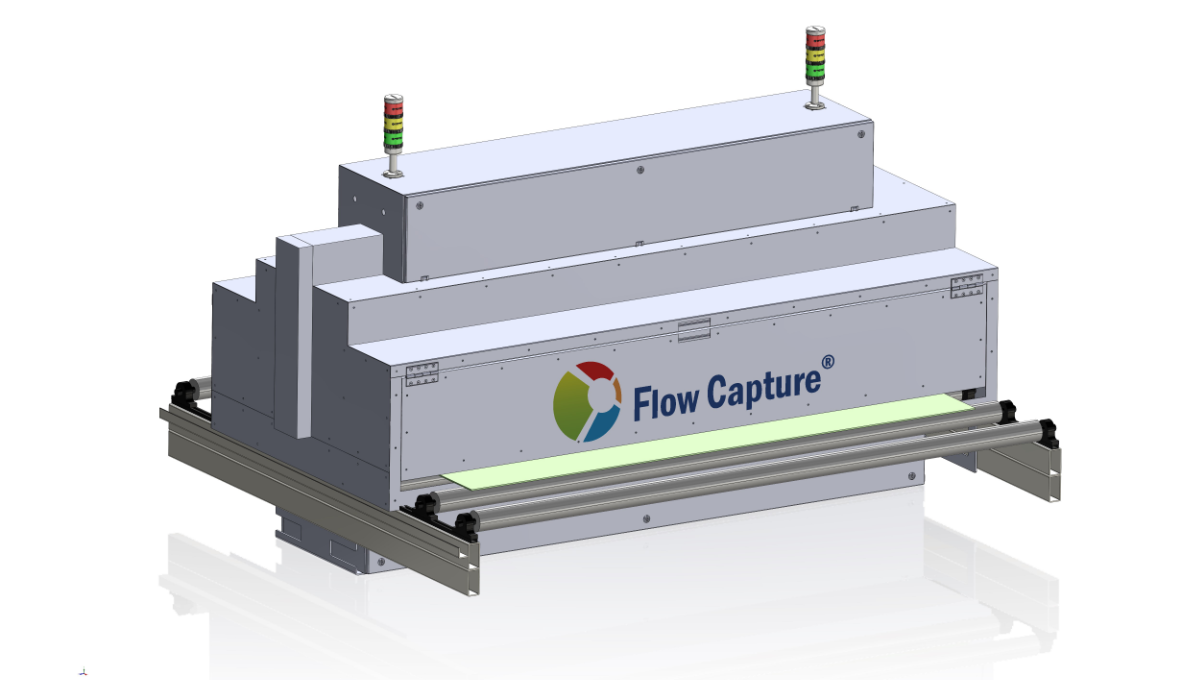

| Model | XrayINLINE™ RCI2X |

|---|---|

| Dimension | 2.7 m Width × 1.5 m Height × 1.3 m Depth |

| WEIGHT | 400-500 kg (depending on the size of the product to scan) |

| Power input | 220-230 VAC, 16 A, 50-60 Hz |

| Scanning speed | 0.178 – 10 meter per min |

| Typical object thickness | 10 mm (other thickness available on request) |

| Max object width | 4 meters |

| Image resolution size | 48 µm/pixel without pixel binning 96 µm/pixel at 2×2 binning |

| X-ray source | Multiple integrated X-ray sources: max power of 500W per source, X-ray energy: 40 – 100 kV, current: 1–12.5 mA |

| Software | XrayINLINE™ 1.4 |

| Ambient environment | Indoor application at ambient T of +10 – +50 C |

| Control system | Security key switch, push button and software activation |

| Installation | Indoor (IP56 available on request) |

| System cooling | Water and air cooled |

| Support | standard 12 months |